Wednesday, June 26 2019 by Alex Stitt

By the end of the mid-19th century a crisis was emerging. In the high-density urban centres of Europe and North America populations had risen dramatically, food sources, particularly the reliance on meat, had meant that existing means of supply were fast becoming unfit for purpose. The task of connecting remote pastoral spheres with the growing malnourished, but capital-rich, conurbations of the old world needed a solution. Two great innovations offered an answer; the steamship, and the burgeoning principle of refrigeration.[1] The majority of food being transported over long distance had been largely confined to grains, cereals, fruits and exotic spices. The efforts of the early 19th century to salt and can meat, though relatively successful for a time, suffered on two counts; firstly they were far too expensive for working class families, and secondly there was not sufficient European demand.[2] Earlier attempts to transport frozen meat had made use of natural cold in the winter months, and of variations of the cold storage bank. Though the Americans successfully delivered frozen meat to Britain in 1875 in a cold bank that used coal-powered fans over large blocks of ice, these methods were often mechanically unreliable and depended on speed. By the 1860s terrestrial refrigeration had been mastered; in Australia the world’s first freezing plant had been effectively set up by Thomas Sutcliffe Mort in Sydney’s Darling Harbour, receiving iced railway carriages soon after. The next two decades would see fierce competition to develop refrigeration engines powerful enough to extend the reach of the ship across the globe.[3]

The attempts to bridge the gap between supply and demand in the frozen food trade fostered intense rivalry. Argentinian business interests were among the first to realise the lucrative potential of shipboard refrigeration. Enlisting French engineer Charles Tellier, the City of Rio de Janeiro in 1868 attempted to transport frozen beef between Montevideo and London using an ammonia absorption plant.[4] Though this machinery broke down during the voyage, it provided the impetus for further experimentation, with the former packet boat Frigorifique in 1876. Refitted by Tellier with an ammonia compression plant, Frigorifique achieved limited success on her outward journey between River Plate and Rouen, delivering only a portion of her frozen meat and poultry in a saleable condition.[5] The New South Wales backed steamship Northam launched an abortive attempt the same year, losing her entire cargo after her ammonia reacted with iron components in her machinery.[6] The French steamer Paraguay followed in 1878 successfully delivering 5,500 frozen carcasses between Buenos Aires and Le Havre by ammonia compression. Inspired by this feat, enterprising Queenslanders, fitted out the Lloyd’s Register classed steamship Strathleven with refrigeration machinery. In 1880, using a pioneering system known as the Bell Coleman Cycle, Strathleven successfully delivered 50 tons of Australian beef and mutton to London, the first to do so.[7] Despite being an historic voyage, Strathleven had relied on speed, taking the much shorter route through the Suez Canal. The question remained; could such a system successfully convey a frozen cargo across the globe without demanding speed?

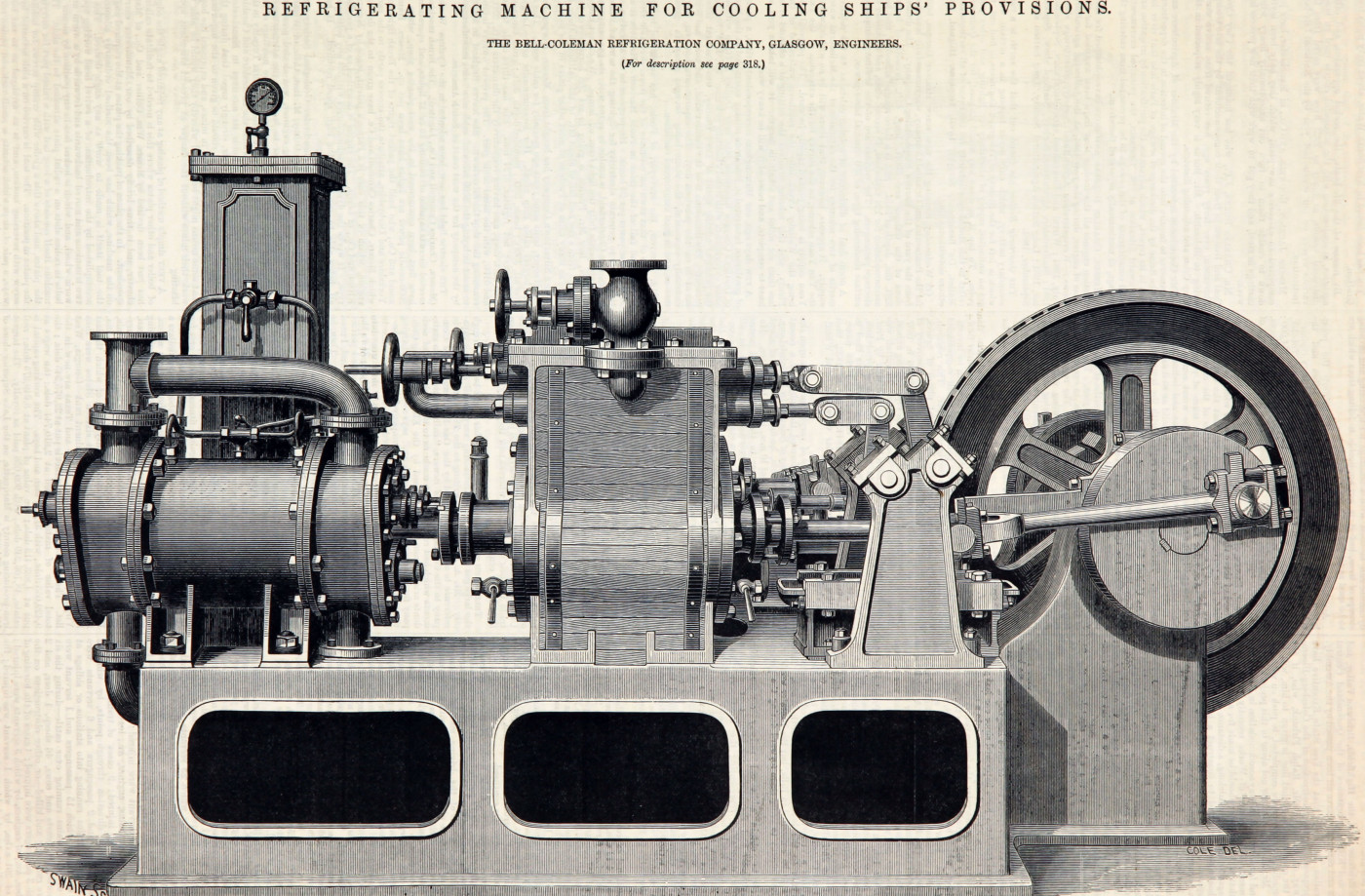

In 1877 Henry and James Bell, of the Glasgow shipping company, John Bell & Sons, had approached Joseph James Coleman with an exciting business proposal. As a Fellow of the Chemical Institute Coleman was chosen for the task of developing a refrigeration process that could successfully preserve frozen goods for long periods. With a patent that same year, the newly formed Bell Coleman Mechanical Refrigeration Company exhibited a machine model at London’s Naval and Submarine Engineering Exhibition. Whereas compression and absorption machines typically circulated brine or ammonia, Coleman’s system used air as the refrigerant.[8] With a capacity to deliver 10,000 cubic feet of cooled air per hour, observers described it as a ‘thoroughly efficient’ example.[9] The Bell Coleman process relies on a compressor to draw air from an insulated cold chamber, before compressing it and depositing it into an air cooler. To prevent the high temperatures of dry compression, water is injected to cool the air. Via a system of drying pipes that remove the moisture, the pressurised cooled air passes to a steam cylinder. The air is then expanded, and the heat is deducted before finally passing back to the cold chamber where the cycle is repeated.[10] In contrast to other designs which required teams of ‘fridge’ engineers, this model was compact; it could be placed against a bulkhead or wall and was easily accessible from all sides by just one engineer. Whilst Bell Coleman machines were in use on land in slaughter-houses and refrigerated stores at Sydney, Rockhampton, Bermuda and Auckland, the design exhibited was intended for the preservation of a ship’s provisions at sea. Already the system was used for cross-Atlantic voyages with the Anchor Line; all that remained was to fully test the capacity of this system with a long voyage at sea. In early 1882, Volume 20 of the British Trade Journal and Export World ended this advertisement with mention of a sailing ship using this machinery that looked set to transport a full cargo of frozen meat from New Zealand-the Dunedin.[11]

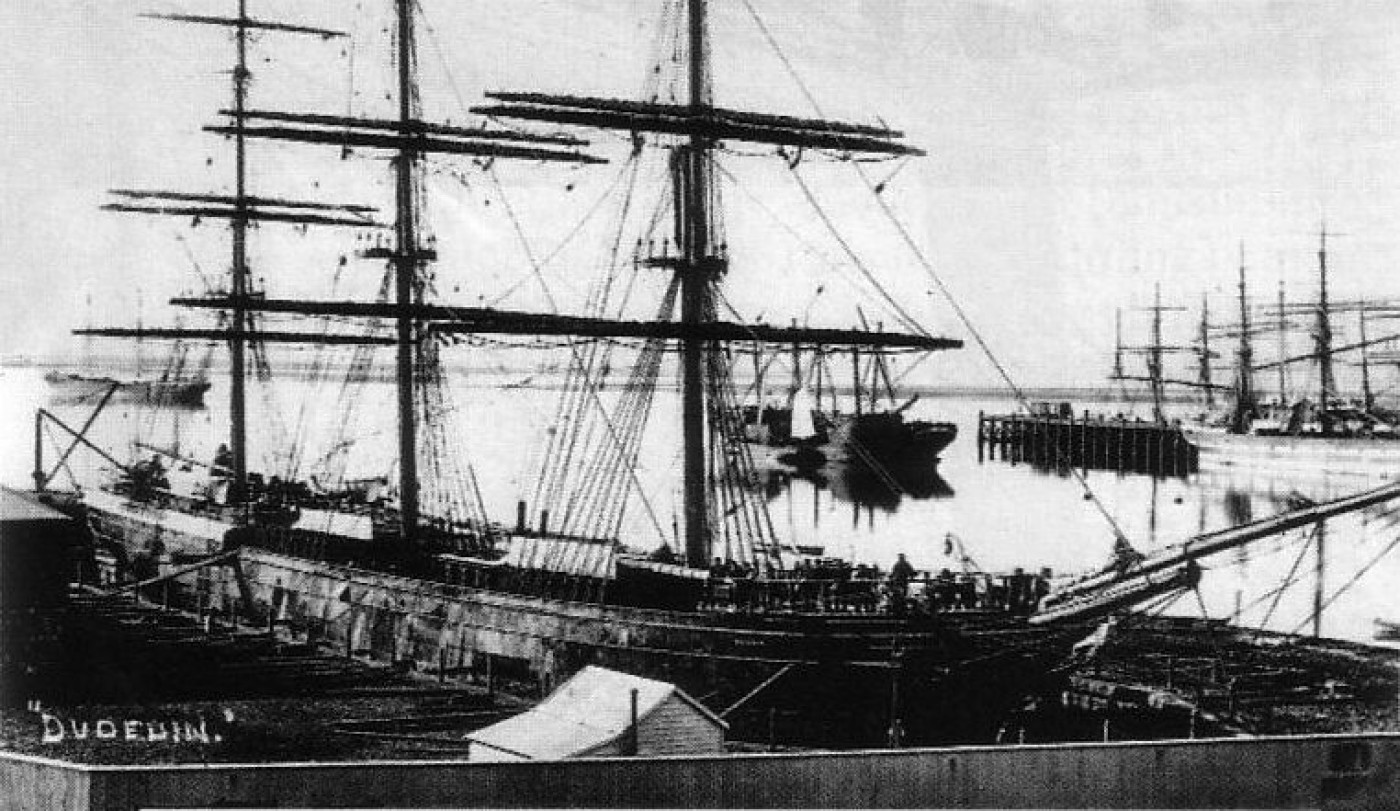

Constructed for the Albion Shipping Company, Dunedin had been built in 1874 at the Port Glasgow shipyard of Robert Duncan & Co. An iron two-decked three-mast ship, she measured 242 feet in length, and had a gross register tonnage of 1320.[12] She was originally intended for the conveyance of emigrants to the growing colony at New Zealand; under Captain John Whitson she gained some standing in shipping circles for completing each of her seven subsequent crossings in under a hundred days. As Strathleven’s successful voyage was hailed in the press, it had caught the attention of William Soltau Davidson, Director of the New Zealand and Australian Land Company (NZALC). A major land association with freehold over roughly 186,000 acres of farmland across New Zealand and Australia, the NZALC was also one of the largest meat and wool producers in the region. After a period of investigation into compression refrigeration machinery, Davidson made a persuasive case to the NZLAC shareholders for an investment in this new technology. For the purposes of cutting fuel costs, saving valuable space on board and to circumvent the issue of infrequent coaling stations, the decision was taken to engage a sailing ship rather than a steamer. Requiring well-built vessels with a proven record of service between Britain and New Zealand, they approached P Henderson & Co, managers of the vessels of the Albion Shipping Company; not long afterwards the Dunedin was offered. The Bell Coleman Mechanical Refrigeration Company were also approached to refit Dunedin in May 1881. Six months later, arriving at Port Chalmers to await her cargo, Dunedin’s pioneering new machinery would be put to the final test, a near 12,000 mile journey.

The arduous process of loading Dunedin’s hold with Merino crossbreed sheep carcasses began in early December 1881. The NZALC had sourced around 10,000; these were then slaughtered at an abattoir in Omauru, and finally transported to Port Chalmers by train. Here the carcasses were sewn in tight-fitting calico bags and finally loaded into Dunedin’s insulated hold. Disappointment and consternation quickly followed. After just seven days of loading, the crankshaft casting of her innovative refrigeration machinery failed and the five hundred carcasses already on board were swiftly dispatched for local sale.[13] Sold at a loss to A. Dornwell, a local butcher, news of the early failure prompted derision in the Otago Witness. An anonymous writer posed the sarcastic question of whether a drop in the number of ewes had been caused by their unwillingness to procreate until they could be ‘respectable frozen, and transported to a market where no Dornwell shall retain it at 1d. per lb?’[14] As well as causing alarm to financial stakeholders, the safety of the new refrigeration equipment was called into question; only two passengers out of an original sixty were willing to retain their tickets to travel aboard the Dunedin.[15]Regardless, the crankshaft was soon repaired and Dunedin set sail from Otago, southeast New Zealand, to London in February 1882. With a frozen cargo that consisted of 4,311 sheep, 598 lambs, 22 pig carcasses, butter, turkeys and chickens, Dunedin was to make an historic voyage across the globe.[16]

Despite the unusual luxury of high-quality meat every night, the onboard machinery was certainly not flawless. On one occasion during the voyage the compressor’s boiler had failed to circulate the cold air; raising a ventilation risk that threatened to cause the boiler to overheat. Faced with the spoliation of his valuable cargo or imperilling the ship, Captain Whitson risked his life sawing holes within the cold chamber, nearly freezing to death in the process.[17] With a line attached to his waist, the crew pulled him in and were able to resuscitate him in time, also saving the cargo. In addition the machinery also consumed around three tons of coal each day; and with a full cargo, and heavy machinery and insulation, not only was the venture and refit expensive, it was also slow. Regardless, the Bell Coleman cycle successfully kept the cargo at a steady temperature of between 12° and 15° Fahrenheit, even in the warm waters of the South Pacific. On the 26th May 1882, Dunedin arrived in London after 98 days at sea; three days later the first successfully frozen meat from New Zealand was sold at Smithfield market at 6½d a lb.[18] Just one carcass had been condemned. Reports also circulated that dozens of London’s discerning butchers were so impressed with the quality of the meat that they had bought several samples, having previously proclaimed never to allow such a commodity in their shops.[19]

By the end of 1882 the New Zealand Herald featured an article proclaiming that the success of refrigeration at sea had opened up the world; New Zealand was now ‘as much a province of England, as easy a source of supply for the London market, as Yorkshire or Devon…’[20] Dunedin’s success, and the realisation of the potential for refrigeration at sea quickly brought with it a rapid change. The following year saw the Houlder Brothers’ steamer Meath, fitted out with refrigeration machinery, marking the beginning of the first regular frozen shipments between Argentina and Europe. 1884 also saw the construction of the steamer Elderslie at Jarrow, the first ship purpose-built to carry frozen meat from New Zealand.[21]With the theory of refrigeration tried and tested, both ammonia and dry-air refrigeration designs were quickly standardised for efficiency of space and cost; increasing the ship’s speed became paramount. With more than 172 shipments of frozen meat, poultry and dairy coming out of South America during the 1880s, systematic and concise rules of classification were desperately required to regulate this flourishing trade.[22] Aware of the great risks of such far-reaching unregulated shipping, Lloyd’s Register relented to requests and published the first official Rules for Refrigeration Machinery in 1898. Drawn up by Robert Balfour, the Society’s first appointed refrigeration engineer, the rules introduced the Refrigeration Machinery Certificate, known more commonly by the notation ‘+RMC’. First awarded to the Blue Anchor Line steamer Wakool, it was quickly deemed acceptable to award certificates to unclassed vessels if the freezing plant conformed to the rules.

By 1906, 108 reefer ships, as they were commonly known, had been classed with Lloyd’s Register; just four years later this number had nearly doubled. [23] To meet the demand specialist engineer surveyors were swiftly appointed to Buenos Aires, and to Christchurch the following year. By the outbreak of the First World War, over 40% of meat consumed in the United Kingdom had been imported. As well as the meat, poultry and dairy market, refrigeration offered exotic fruits and vegetables that could be enjoyed for the first time all year round. With the construction of the refrigerated ‘Empire Food Ships’ of the 1930s, economies like those of Australia and New Zealand had been firmly established as agricultural world leaders. These ships would pave the way for the post-war innovation of the 1940s and 50s; ships that improved insulation and minimised the loss of chilled air. Finally, in 1968 Lloyd’s Register classed two historic sister ships of the Port Line; the Port Caroline and the Port Chalmers, the largest refrigerated cargo ships afloat, measuring over 16,200 gross register tons.[24] Today, in the age of containerisation, with each box possessing its own freezing unit, around 100 million tons of frozen cargo is carried per year. Continuing her trade for the next eight years, Dunedin was quickly surpassed by entrepreneurial vessels and shipping lines eager to capitalise on the refrigeration boom. By the time she was mysteriously lost in 1890 with 35 hands onboard, the trade she had helped to forge had already changed global exportation forever. ‘The ship that has accomplished a feat which must long have a place in commercial, indeed, in political annals, is the Dunedin, belonging to the Albion Shipping Line.’[25] The Dunedin remains to this day a monument to dynamic engineering, and it is for this reason that she is secured a place in our First and Famous list.

[1] Maritime Science and Technology, Nigel Watson, ed. Barbara Jones, pg. 92

[2] Agricultural History Review, volume 60, no. 2, Rebecca, J. H. Woods, ‘Breed, culture and economy: The New Zealand frozen meat trade 1880-1914, pg. 289

[3] Agricultural History Review, volume 60, no. 2, Rebecca, J. H. Woods, ‘Breed, culture and economy: The New Zealand frozen meat trade 1880-1914, pg. 291

[4] Maritime Science and Technology, Nigel Watson, ed. Barbara Jones, pg. 92

[5] Cargo Lines: An Illustrated History, Lord Ambrose Greenway, pg. 11

[6] To Feed a Nation, Keith Thomas Henry Farrer, pg. 53

[7] Lloyd’s Register, 250 years of service, Nigel Watson, ed. Barbara Jones, pg. 140

[8] Cargo Lines: An Illustrated History, Lord Ambrose Greenway, pg. 11

[9] British Trade Journal and Export World, Volume 20, pg. 303

[10] Thermal Engineering, B. K. Sarkar, pg. 586

[11] British Trade Journal and Export World, Volume 20, pg. 303

[12] Lloyd’s Register Survey Report, Iron 12471

[13] Sail to New Zealand, David Savill, pg. 120

[14] Agricultural History Review, volume 60, no. 2, Rebecca, J. H. Woods, ‘Breed, culture and economy: The New Zealand frozen meat trade 1880-1914, pg. 293

[15] Sail to New Zealand, David Savill, pg. 120

[16] Agricultural History Review, volume 60, no. 2, Rebecca, J. H. Woods, ‘Breed, culture and economy: The New Zealand frozen meat trade 1880-1914, pg. 288

[17] Sail to New Zealand, David Savill, pg. 121

[18] Sail to New Zealand, David Savill, pg. 120

[19] Otago Daily Times, issue 6419, 8 September 1882

[20] New Zealand Herald, 12 October 1882, pg. 6

[21] Cargo Lines: An Illustrated History, Lord Ambrose Greenway, pg. 11

[22] Maritime Science and Technology, Nigel Watson, ed. Barbara Jones, pg. 92.

[23] Lloyd’s Register, 250 years of service, Nigel Watson, ed. Barbara Jones, pg. 141

[24] Lloyd’s Register, 250 years of service, Nigel Watson, ed. Barbara Jones, pg. 141

[25] Otago Daily Times, issue 6375, 19 July 1882