- Related documents Related

- Complete documents list Documents

- Report ship? Report?

Use the data export button to extract customised data sets from the Ship Plan and Survey Report Collection. Available in TSV and CSV formats.

Name of ship as recorded on the record

Ship name

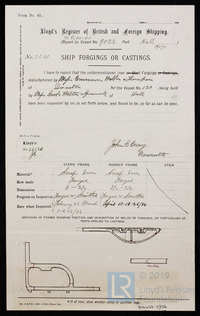

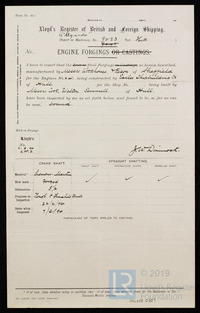

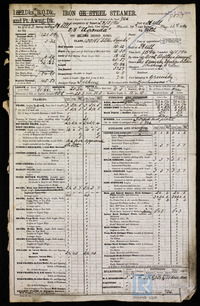

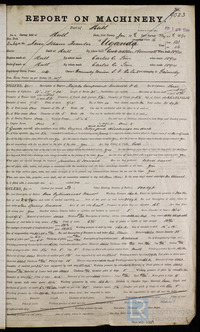

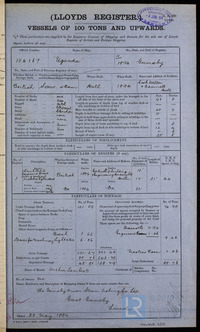

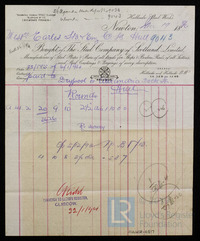

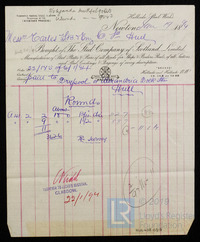

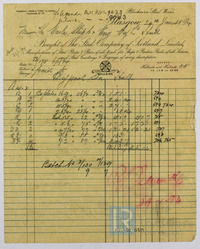

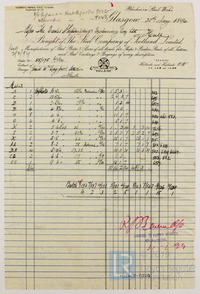

Uganda ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Ship Forgings or Castings Form for Uganda, 19th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

The process of transferring a vessel to water, but not necessarily her completion.

Launch Date

04/05/1894 ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Ship Forgings or Castings Form for Uganda, 19th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

Unique identifier for a given ship, it is assigned by a builder.

Yard no

120 ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Ship Forgings or Castings Form for Uganda, 19th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

Location where a vessel’s survey was undertaken.

Location of Survey

Hull ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894 )

Newcastle ( Ship Forgings or Castings Form for Uganda, 19th May 1894 1894 )

Newton; Hull ( Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894 )

Glasgow; Hull ( Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

Predominant material(s) utilised in a vessel’s construction.

Material of construction

Iron ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Ship Forgings or Castings Form for Uganda, 19th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

Confirmation as to whether the vessel was equipped with refrigeration machinery to aid in the transport of frozen or chilled cargo/goods.

Refrigeration machinery fitted for cargo purposes?

No ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Ship Forgings or Castings Form for Uganda, 19th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

Does the vessel possess an auxiliary power source?

Auxillary

No ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Ship Forgings or Castings Form for Uganda, 19th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

Is electric lighting fitted to the vessel?

Electric light fitted?

No ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Ship Forgings or Castings Form for Uganda, 19th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

Name of surveyor.

Surveyor

John C Craig ( Ship Forgings or Castings Form for Uganda, 19th May 1894 1894 )

J W Dimmock ( Engine Forgings Form for Uganda, 7th March 1894 1894 )

Robert Williamson ( Iron Steamer report for Uganda, 28th May 1894 1894 )

James Innes ( Report on Machinery for Uganda, 25th May 1894 1894 )

A Kidd ( Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894 )

Abbreviations of the names of ports with Lloyd’s Register survey offices.

Port of survey abbreviations

Hul ( Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894 )

The individual and/or organisation listed

Ship owner

The Grimsby Union Steam Fishing Co Ltd ( Iron Steamer report for Uganda, 28th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894 )

Grimsby Union Steam Fishing Co Ltd ( Report on Machinery for Uganda, 25th May 1894 1894 )

Recorded information related to a vessel’s movements.

Voyage information

Hull; Fishing ( Iron Steamer report for Uganda, 28th May 1894 1894 )

Physical arrangement of a ship’s masts, sails and rigging.

Type and configuration of the engine(s) supplied for a vessel.

Engine type

Triple Compound Inverted Direct Acting ( Report on Machinery for Uganda, 25th May 1894 1894 )

3 Crank Triple Compound Direct Acting Vertical Inverted Cylinders ( Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894 )

The port in which a vessel is registered or permanently based.

Port of registry

Grimsby ( Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894 )

The year in which a vessel’s construction is completed.

Year of ship completion

1894 ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Ship Forgings or Castings Form for Uganda, 19th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

The individual and/or organisation listed as having been responsible for constructing the vessel. This can/may be the same as the owner and/or manager.

Shipbuilder

Cook, Welton & Gemmell ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Ship Forgings or Castings Form for Uganda, 19th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

The port or place in which the vessel’s construction took place, at the time of writing.

Place of build

Hull ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Ship Forgings or Castings Form for Uganda, 19th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

A vessel’s means of propulsion.

Propulsion

Steam ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Ship Forgings or Castings Form for Uganda, 19th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

Is the steamer assisted by sail?

Sail assisted steamer

No ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Ship Forgings or Castings Form for Uganda, 19th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

Is machinery fitted at the aft of the vessel?

Machinery aft?

No ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Ship Forgings or Castings Form for Uganda, 19th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

Generally a smaller additional auxiliary boiler (often used while the vessel is at port).

Is a donkey boiler fitted?

No ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Ship Forgings or Castings Form for Uganda, 19th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

Name of the Proving House responsible for the public testing and certification of a vessel’s anchors and/or chain cables.

Lloyd's Proving House?

No ( Plan of Steel Boiler for Uganda, 4th July 1893 1893, Plan of Midship Section for Uganda, 1894 1894, Plan of Beam Arrangement for Uganda, 1894 1894, Form from W Rowell to The Secretary of Lloyd's Register forwarding Midship Section for Uganda, 29th May 1894 1894, Ship Forgings or Castings Form for Uganda, 19th May 1894 1894, Engine Forgings Form for Uganda, 7th March 1894 1894, Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland, Ltd for Uganda, 19th January 1894 1894, Receipt for materials manufactured by The Steel Co of Scotland Ltd for Uganda, 19th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 24th January 1894 1894, Receipt for Boiler Plates manufactured by The Steel Co of Scotland Ltd for Uganda, 30th January 1894 1894 )

Location of construction for a vessel’s engines.

The listed port to which a given vessel belongs.

Port belonging to

Grimsby ( Iron Steamer report for Uganda, 28th May 1894 1894, Report on Machinery for Uganda, 25th May 1894 1894 )

undefined ( Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894 )

Classification symbol assigned to a vessel by Lloyd’s Register’s Classing Committee denoting the quality of construction and maintenance.

Classification

100A1 Steam Trawler; 1 Dk; +LMC 5,94 ( Iron Steamer report for Uganda, 28th May 1894 1894 )

+LMC 5,94 ( Report on Machinery for Uganda, 25th May 1894 1894 )

The name of the port/place of destination given.

Destined voyage

Fishing ( Iron Steamer report for Uganda, 28th May 1894 1894 )

A ship’s total internal volume in ‘register tons’ (replaced by gross tonnage post 1982).

Date in which construction of a vessel’s engines were completed.

Year of engine build

1894 ( Report on Machinery for Uganda, 25th May 1894 1894, Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894 )

An officially licensed mariner (post 1850) holding ultimate command and responsibility for a vessel.

Master

Arthur Lambert ( Form for Vessels of 100 Tons & Upwards for Uganda, 28th May 1894 1894 )

Report an issue with this ship

Have you noticed missing or incorrect data or images for this ship?

Please let us know and we will rectify the issue as soon as possible.